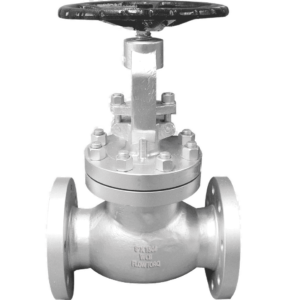

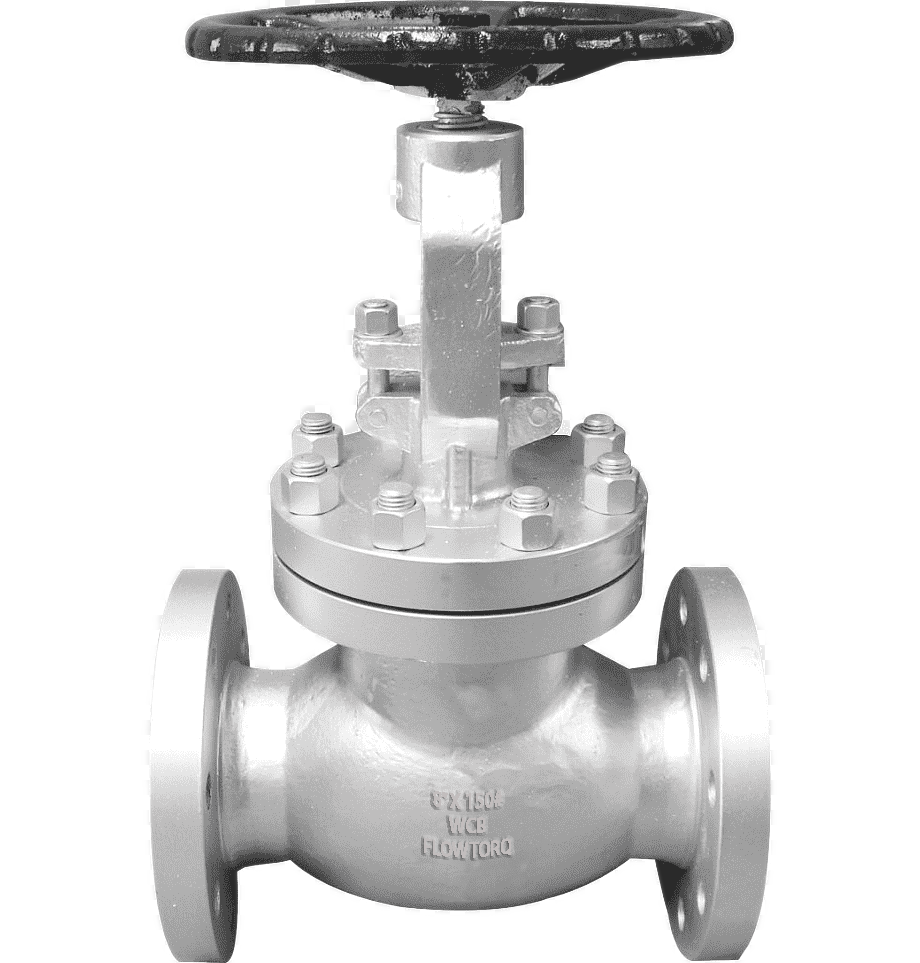

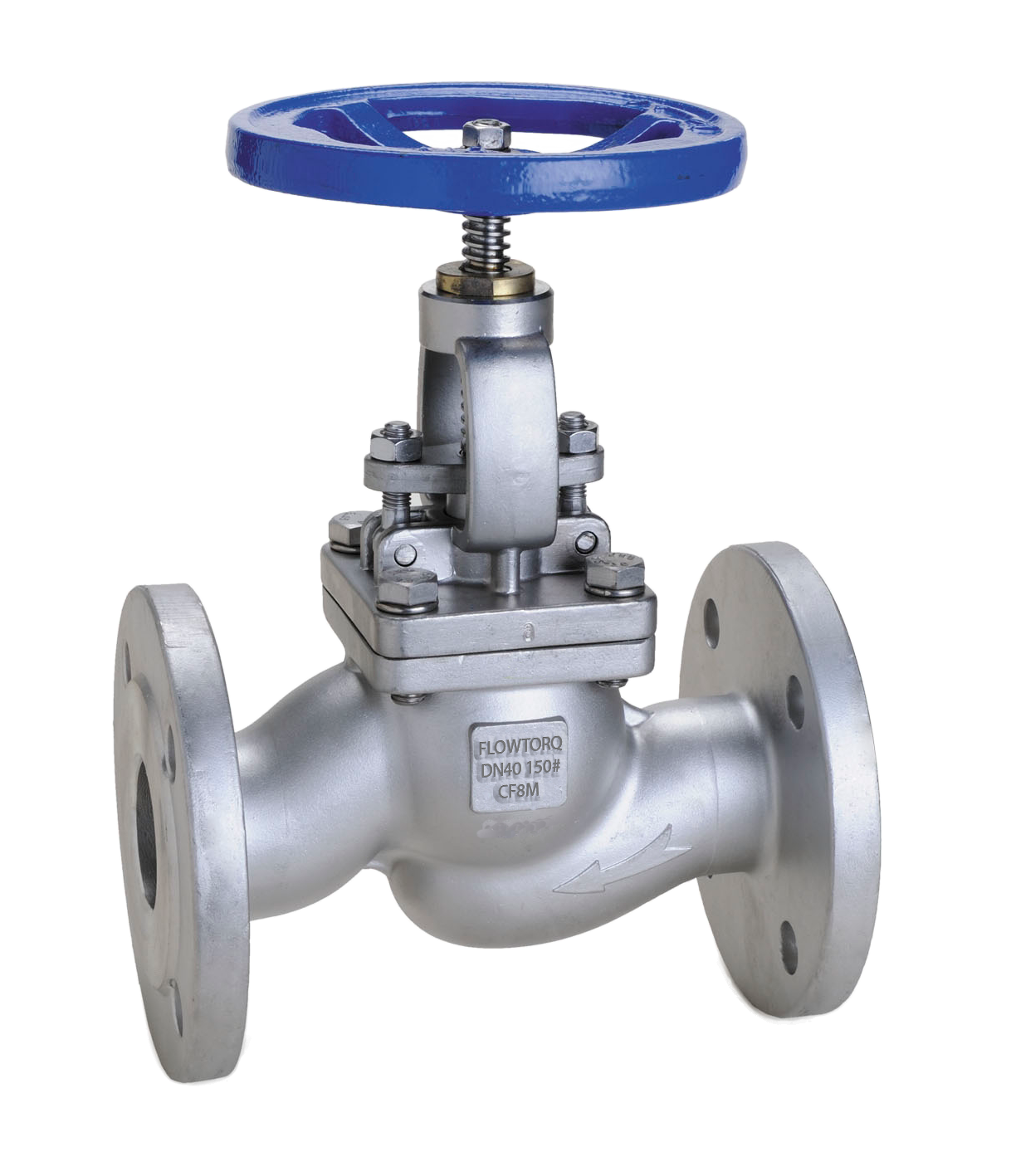

Globe Valves - BS 1873

Flowtorq Engineering is best manufacturer of globe valves. A globe valve, different from gate valve or ball valve, is a type of valve used for flow control or regulating flow in a pipeline. It is designed as per BS 1873 and BS 5352 standards. It consists of a movable plug or disc element and a stationary ring seat in a generally spherical body. Globe valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle. This has an opening that forms a seat onto which a movable plug and can be screwed in to close (or shut) the valve. The plug is also called a disc. In globe valves, the plug is connected to a stem which is operated by screw action using a handwheel in manual valves. Typically, automated globe valves use smooth stems rather than threaded and are opened and closed by an actuator assembly.

Detailed Specifications as per BS 1873

Cast Steel Globe Valves 150# to 2500#

-

Carbon Steel - WCB, WCC

-

Stainless Steel - CF8, CF8M, CF3, CF3MÂ Â

-

Alloy Steel - WC6, WC9, WC12

-

BrassÂ

-

Bronze

-

Aluminum Bronze

-

Duplex and Super Duplex - CN7M, 4A, 6A, 5A

-

Hastelloy ad other grades - HAstelloy, Monel, etc.

-

13% Cr. Steel (Trim 1)

-

13% Cr. Steel + ST6 Stellite (Trim 8)

-

ST6 Stellite (Trim 5)

-

SS304

-

SS316

-

Inconel

-

Monel

-

All Trim as per API 600

-

Other Trim as per Client requirement

-

Flanged

-

Butt Weld

-

RTJ (Ring Type Joint

-

Limit Switches

-

Position Indicators

-

BS 1873

-

ASME B 16.34

-

API 598 / BS 12266-1

-

Other End User Standards

-

Hand Wheel Operated

-

Gear Operated

-

Electric Actuator Operated

-

Pneumatic Actuator Operated

-

Motorized (Electric)

Forged Steel Globe Valves 800# to 2500#

-

Carbon Steel - A105

-

Stainless Steel - F304/L, F316/L

-

Alloy Steel - F11

-

Duplex and Super Duplex - F51

-

13% Cr. Steel (Trim 1)

-

13% Cr. Steel + ST6 Stellite (Trim 8)

-

ST6 Stellite (Trim 5)

-

SS304

-

SS316

-

Inconel

-

Monel

-

All Trim as per API 600

-

Other Trim as per Client requirement

-

Screwed / Threaded (Female)

-

Socket Weld

-

Pipe End

-

Welded Flanges

-

Welded Nipples both sides

-

Socket Weld X Threaded

-

Scoket Weld X Pipe End

-

Limit Switches

-

Position Indicators

-

BS 5352

-

ASME B 16.34

-

API 598 / BS 12266-1

-

Other End User Standards

-

Hand Wheel Operated

-

Electric Actuator Operated

-

Pneumatic Actuator Operated

-

Motorized (Electric)