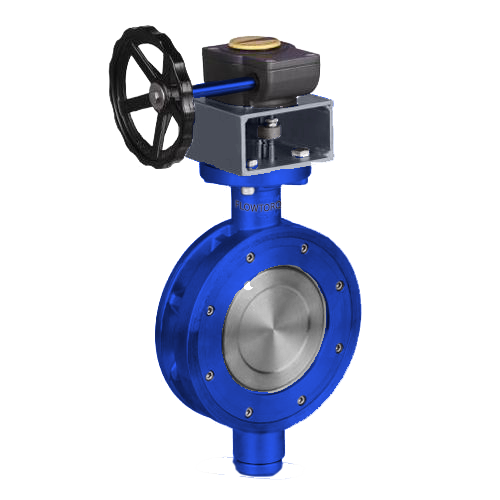

Butterfly Valves - API 609, BS 5155, ASME B 16.34, ISO 5752

Flowtorq Engineering is best manufacturer of butterfly valves. Butterfly valves are mainly used to shutt off, distribute and change the direction of fluid medium flow in pipeline. Sometimes butterfly valves are used for flow regulation and control. Similar to Ball valves, butterfly valves are generally quarter turn operated valves, i.e. needs to be operated with a rotation of 90 degrees and a small turning torque to close tightly. These valves are operated by lever, Gear operated handwheel or pneumatic / electric actuators. The body is usually very short in running lenght as compared to other types of valves and is usually through in cross sectional area. This body cavity provides a direct flow path with little resistance for flow and very little pressure drop. Butterfly Valves are designed as per BS 5155, API 609, ASME B 16.34 and ISO 5752 standards.

Butterfly ValveAPI 609 Specifications

Steel / Iron Butterfly Valves 150# to 600#

-

Carbon Steel - WCB, WCC

-

Cast Iron, Ductile Iron, Grey Iron

-

Stainless Steel - CF8, CF8M, CF3, CF3M¬†¬

-

Alloy Steel - WC6, WC9, WC12

-

Brass¬

-

Bronze

-

Aluminum Bronze

-

Duplex and Super Duplex - CN7M, 4A, 6A, 5A

-

Hastelloy ad other grades - HAstelloy, Monel, etc.

-

Disc - Carbn Steel, SS304/L, SS316/L, Duplex, Monel, HAstelloy

-

Stainless Steel for Disc, Stem and seat retainer rings

- Seats - EPDM, NITRILE, PTFE, RTFE, PEEK, NYLON, TEFLON, VITON, etc.

- Metal Seated - SS + Tugsten Carbide coating (TC), Stellited ST6

- Other Trim as per Client requirement

-

Flanged

-

Wafer

-

Lug Type (Semi Lug and Full Lug)

-

Limit Switches

-

Position Indicators

-

Gear Operated Handwheel

-

BS 5155, ISO 5752, API 609, ASME B 16.34

-

API 598 / BS 12266-1 / FCA

-

Other End User Standards

-

Hand Lever Operated

-

Gear Operated

-

Electric Actuator Operated

-

Pneumatic Actuator Operated

-

Motorized (Electric)