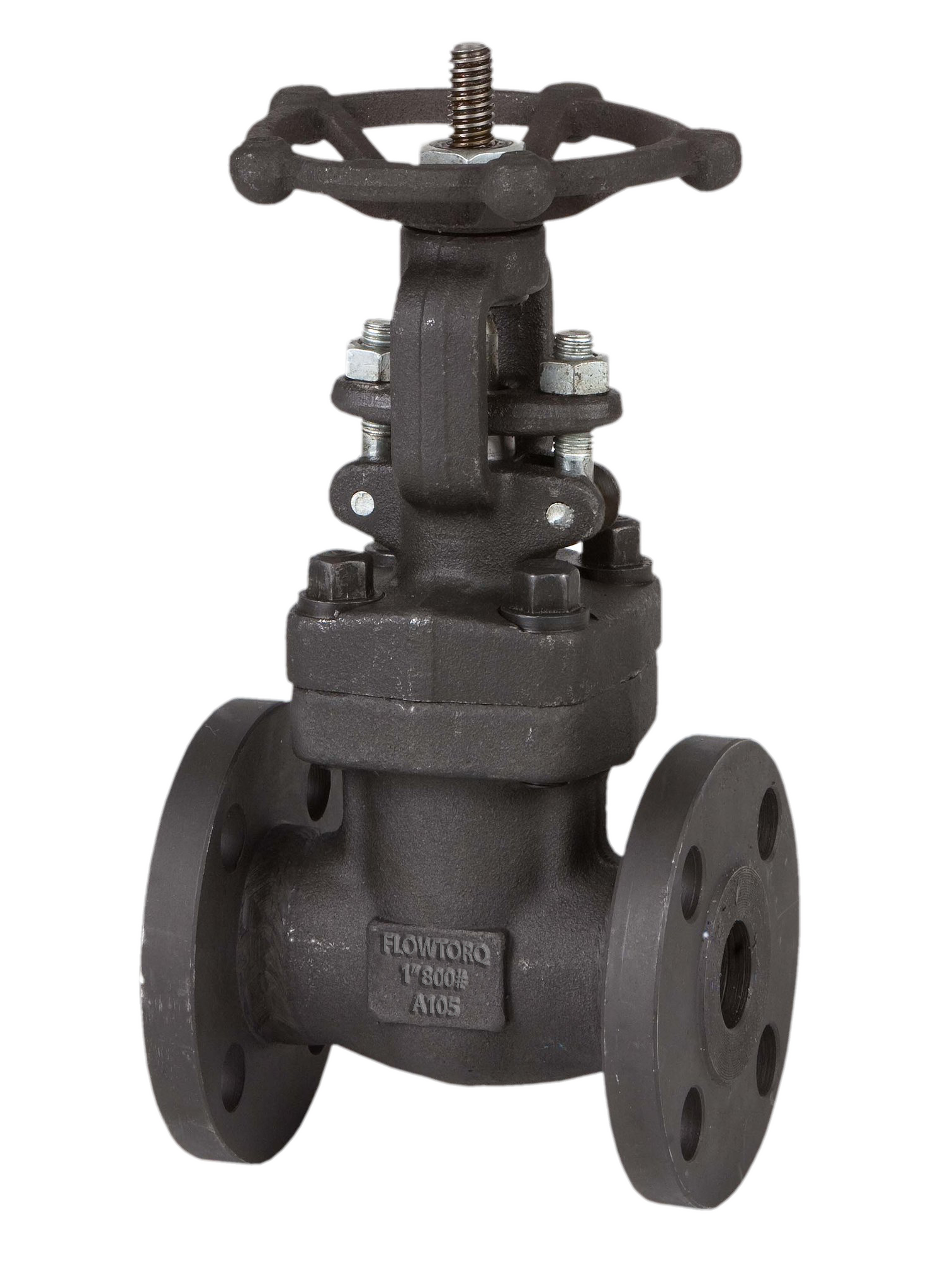

API 602 Forged Steel Gate Valves

Forged steel gate valve is a type of gate valve whose body parts are made of forging material. Similarly to large gate valves, the gate of the forged steel gate valve moves along the vertical plane perpendicular to centre axis of flow cavity or bore. These valves is mainly in use for on-off function in the process pipeline system. Forged steel gate valves are widely preferred valves. These are desinged and manufactured as per API 602 standards and are usually available in size range from 1/2" to 2" and lastly pressure rating like 800#, 1500# and 2500#.Â

Gate Valve Specifications

Forged Steel Gate Valves 800# to 2500#

-

Carbon Steel - A105

-

Stainless Steel - F304/L, F316/L

-

Alloy Steel - F11

-

Duplex and Super Duplex - F51

-

13% Cr. Steel (Trim 1)

-

13% Cr. Steel + ST6 Stellite (Trim 8)

-

ST6 Stellite (Trim 5)

-

SS304

-

SS316

-

Inconel

-

Monel

-

All Trim as per API 600

-

Other Trim as per Client requirement

-

Screwed / Threaded (Female)

-

Socket Weld

-

Pipe End

-

Welded Flanges

-

Welded Nipples both sides

-

Socket Weld X Threaded

-

Scoket Weld X Pipe End

-

Limit Switches

-

Position Indicators

-

API 602

-

ASME B 16.34

-

API 598 / BS 12266-1

-

Other End User Standards

-

Hand Wheel Operated

-

Electric Actuator Operated

-

Pneumatic Actuator Operated

-

Motorized (Electric )